BAWAT: A simple, pragmatic approach to the BWTS paradigm

Under the auspices of the Institute of Marine Engineering, Science & Technology (IMarEST) UAE Branch, Bawat from Denmark sponsored an enriching knowledge sharing session focusing on their unique patented technology that represents perhaps the simplest technology within ballast water treatment.

The evening technical meeting was attended by 87 delegates from companies such as ClassNK, e-marine, UASC, Planet Blue Marine, Goltens, Drydocks World Dubai, McDermott Middle East, Jawar Al Khaleej Shipping, Pisces Vessel Consultants, Carmelo Caruana, Endress+Hauser, Hapag-Lloyd , Zenith Ship Management, Consilium Middle East, ABS, Eships, Central Ship Management, KOTC, Radio Holland Middle East, Key Ship Management, Vale Oman, Topaz Energy & Marine, MSH Ship Management, Dubai Maritime City Authority, ADNOC Logistics, Federal Transport Authority, Al Bedaya Services, PSN Lifesciences International, Vedam Consultancy, Auburn Ship Management, Greenwich Marine, Dubai Maritime City Authority, Avant Consulting, Orion Risk Group, ADSB, Bahri Ship Management, GMS, Silver Star Ship Management, Abu Dhabi Ports, Triton Maritime, Dockendale Ship Management, Transgulf Energy, Cleghorn Wilton & Associates, Red Sea Marine Management, Unique Aurus and Emarat Maritime.

In his welcome speech, Nikeel Idnani, Honorary Secretary IMarEST UAE, highlighted the fact that ships must install a Ballast Water Treatment System prior to the first IOPP renewal survey after 8 Sept 2019. Approximately $2 million CapEx per ship will be the financial outlay to comply with this regulatory behemoth. He suggested a least disruptive technology will mitigate prospective costs in meeting the BWM Convention obligation. Quintessential benefits include a unique system that does not interfere with revenue earning cargo operations, does not need UV, filters nor chemicals, optimizes energy efficiency by exploiting the engine’s waste heat yet complies with the IMO D2 performance standard.

In his keynote address, Klaus Andreasen, Senior Sales Manager Bawat AS, pointed out that Bawat’s revolutionary BWMS represents a breakthrough technological advance in ballast water treatment. The unique in-voyage system ensures zero impact on ship performance and zero disruption to cargo and ballast operations while the vessel is in port. Bawat’s BWMS is an effective technology based on pasteurization with no use of chemical compounds, UV-radiation or filters. Pasteurization is a combination of heat and time and is a well-known process from the food industry. The ballast is pumped through a pasteurizing unit, consisting of plate heat exchangers and a retention tank. When passing through the Pasteurization Unit, the BW is heated up and kept, while still in flow, within the Retention Section for up to approximately 75 seconds, depending of the pasteurizing temperature. The heating takes place in one or two plate heat exchangers and the heat is provided by onboard surplus heat sources – e.g. main engine jacket cooling water or exhaust heat economizers. After pasteurization, the BW passes through the regeneration section, acting as a pre-heater of the incoming ballast water, and cooler for the outgoing ballast water, taking the temperature down to 4-7 degrees higher than the inlet temperature. When the ballast water has been treated in the pasteurizing unit it fulfills the Ballast Water Conventions outlet criteria in both USCG and IMO’s way of testing. No holding time or retreatment is necessary. There are no filters in the process, neither is use of chemicals required. Since the water fulfills the Ballast Water Conventions outlet criteria when treatment in the pasteurizing unit is completed, it gives the opportunity to treat the water in no less than 4 different ways. Utilizing pasteurization for water treatment avoids the risk of toxicity to nature and humans. Klaus enthusiastically emphasized the economic advantages for ship-owners viz. Bawat BWMS flexibility in offering four different treatment options in the same system, and adaptable to any ship size.

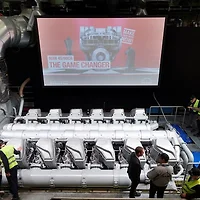

As an alternative quick response to fixed onboard systems, Bawat has developed a cost-effective, energy-efficient containerized ballast water treatment system. This offers an onshore mobile treatment service to ship owners for water treatment at ports and terminals. Further to this the mobile solution could be used as a backup service for ports for ship’s being unable to discharge treated water, as well as ships yards may see a mobile solution as an opportunity to fulfill the needs to treat ballast water from docking ships. The mobile solution includes heat recovery, no use of consumables and with no end residue for treatment fits very well with Bawat’s mission of developing sustainable solutions for a cleaner world.